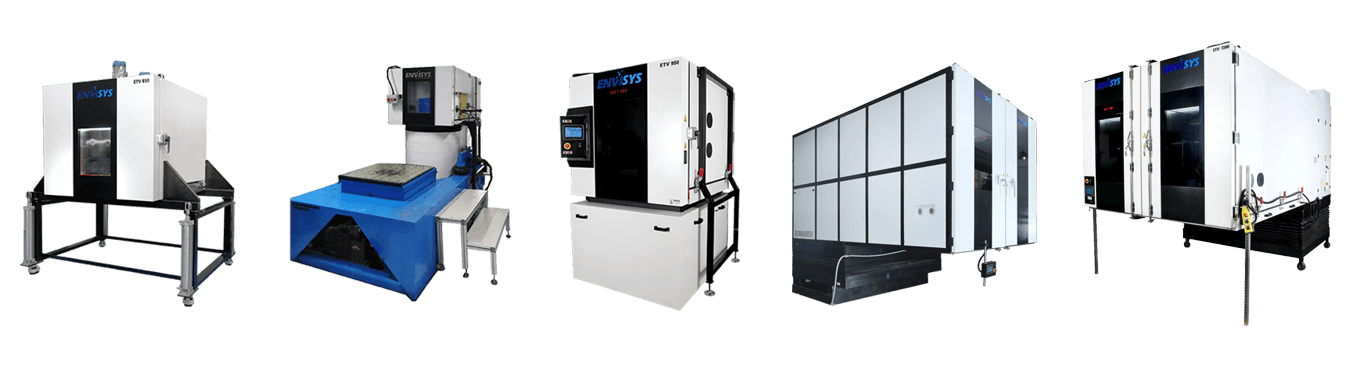

ETV-SERIES

Vibration Shaker Climatic Testing Temperature Chambers Manufacturers & Suppliers USA, UK, Russia

Environmental Testing Chambers With Vibration Shaker Interface

Easy set-up | 18/7 Technical Support

Get Info Today!

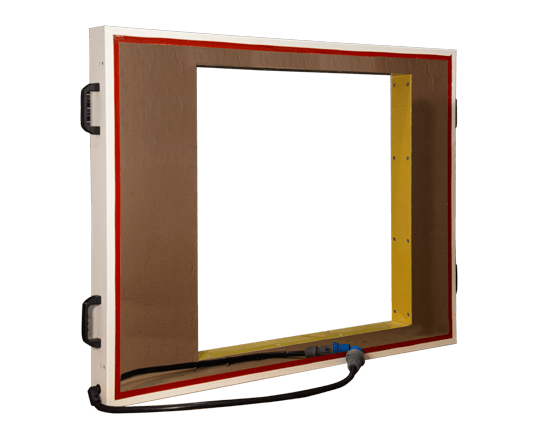

Armature Hood

Slip Table Hood

| Parameters | Specifications |

|---|---|

| ETV150 - 40T/70T 40H/70H | 550X400X700 MM |

| ETV300 - 40T/70T 40H/70H | 650X600X800 MM |

| ETV600 - 40T/70T 40H/70H | 800X850X900 MM |

| ETV950 - 40T/70T 40H/70H | 1000X100X950 MM |

| ETV1400-40T/70T 40H/70H | 1100X1350X950 MM |

| Volume | 150,300,600,950&1400 Liters |

| Temp | -40 / -70 to 180°C |

| Relative Humidity | 10 to 95% RH |

Vibration testing in a climatic chamber allows the product to be subjected to a variety of tests, including vibrations, temperature fluctuations, and climatic variations. This test evaluates an equipment's or component's resistance to a combination of climatic and mechanical stresses which can impair performance in regular use. Aerospace and automotive components are two of the most common types of items that must undergo such tests to assure user safety and reliability.

Envisys is one of the globally prominent manufacturers and suppliers of Vibration Climatic Testing Chamber. Our vibration shaker testing chamber is designed and manufactured to meet the specific needs of our clients while also complying with a number of global standards. Moreover, our vibration shaker test chambers have been highly endorsed by our clients because of their flexibility to adjust to various shakers, test modes combinations with low temperature, high temperature, and humidity. Our vibration climatic test chambers are developed with unique features to match the control parameters given in the specification, such as temperature, humidity (optional), and 3 axis vibration controls.

Envisys’ vibration testing chambers are made to work with either electrodynamic or mechanical vibration systems, depending on the customer's request. While each model is built to standard specifications, it can also be custom designed to meet a range of rigorous test requirements. With our base in many top nations across the globe such as the USA, UK, and Russia, Envisys’ commercial vibration chambers are built to match the latest innovation and are up-to-date in terms of systems and techniques. To maintain reliability and consistency at each stage of manufacturing, we constantly update our technology and methodologies. We have shown incredible resiliency and fortitude over the years. We are committed to increasing productivity by focusing on constant innovation and improvement of our products and people.

Varieties of