The automotive industry works around absolutes. A vehicle either starts on a winter morning at -40°C or it doesn’t. Electronic control units either function flawlessly through desert heat or they fail. For manufacturers, there’s no middle ground when it comes to product reliability increasingly, there’s no room for error when billions of dollars hang in the balance.

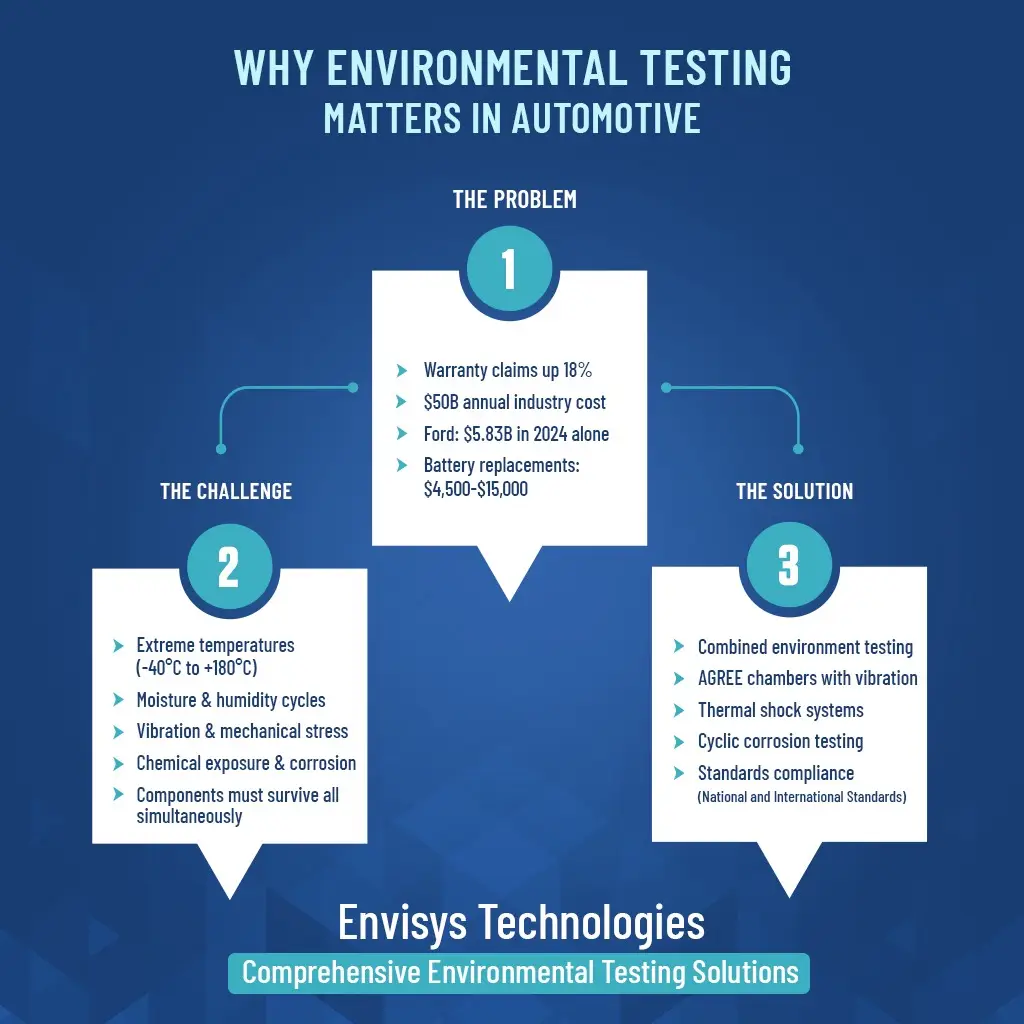

Automotive warranty claims worldwide increased 18% between 2023 and 2024, with the industry estimated to pay out $50 billion annually. Ford alone paid $5.83 billion for warranty claims in 2024, while GM had a 23% year-over-year increase in the cost of warranties. Behind these numbers lies an entrenched problem: throughout its life cycle, an automotive part needs to perform predictably across temperature swings, vibration cycles, humidity variations, and chemical exposure that would destroy most consumer products within weeks.

The Real Cost of Environmental Failures

When automotive parts fail in the field, the financial damage ripples through several levels. The direct warranty claim-the average for which is $150 to process in the automotive sector-represents merely the visible part of a much larger problem.

Consider what happens when those electronic control units exhibit intermittent failures after being exposed to thermal cycling. The manufacturer will incur parts replacement costs, diagnostic labor at the dealership level, customer vehicle downtime, expedited shipping, and possible safety investigations. For electric vehicle traction batteries, the cost of individual replacement can run upwards from $4,500 to more than $15,000.

The major automobile manufacturers process more than 100,000 warranty claims per year. When patterns emerge that show systematic weaknesses in the environment, the reputational damage is often greater than the direct financial hit. The actions of Ford and GM have included adding significant additional accruals to prior periods, which implies they continually underpredicted warranty costs for vehicles already in the field.

Engine management faults, the number one extended warranty claim, frequently trace back to electronic components that degraded under environmental stress. Sensor failures occur when designers underestimated the combined effects of temperature cycling, moisture exposure, and vibration.

Why Traditional Testing Approaches Fall Short

Standard qualification testing often evaluates environmental factors in isolation. A component might pass temperature testing, then fail when that same temperature variation occurs while simultaneously experiencing vibration and exposure to road salt spray. Real-world automotive environments don’t wait for one stress to complete before introducing the next.

The challenge intensifies with electric vehicles and advanced driver assistance systems. Modern vehicles contain exponentially more electronic components, each with environmental vulnerabilities. Battery management systems must maintain precise thermal control while exposed to varying ambient conditions. LiDAR sensors need consistent performance whether operating in Arizona summer heat or Minnesota winter cold.

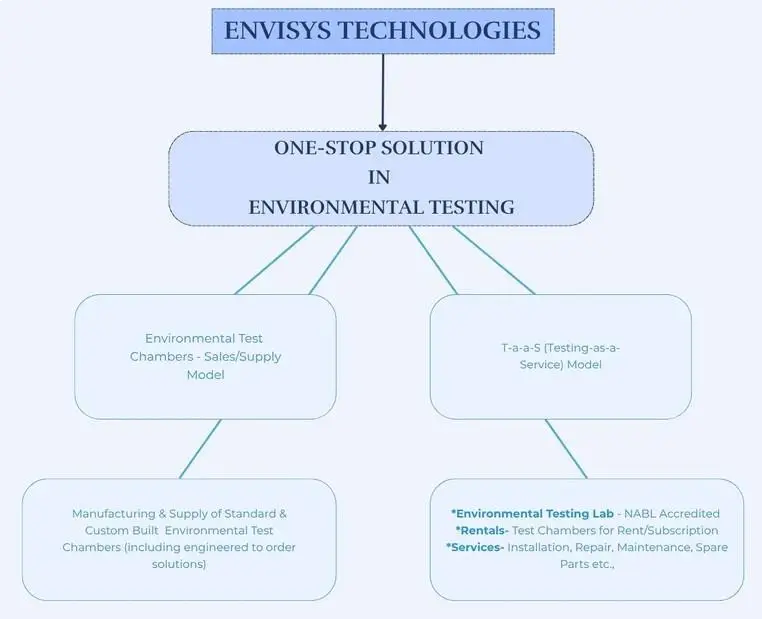

How Envisys Technologies Addresses Environmental Testing Challenges

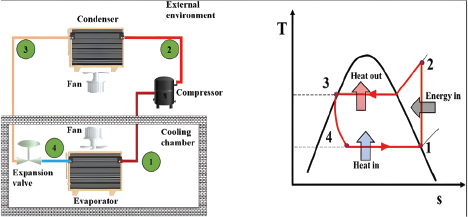

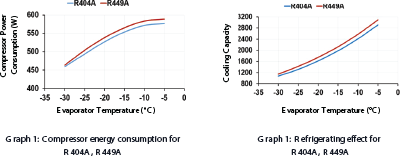

Environmental testing demands integrated test systems that replicate the multi-stress environments vehicles actually experience, coupled with precise control to ensure repeatable results.

Envisys Technologies specializes in combined environment test systems that simultaneously apply temperature, humidity, and vibration stresses. When validating electronic control units to standards like ISO 16750 and SAE J1211, components are exposed to electrical transients while experiencing mechanical vibration and thermal cycling, mimicking an ECU mounted near an engine.

The company’s AGREE chambers integrate seamlessly with vibration systems, enabling temperature and humidity conditioning during mechanical stress testing. This matters because failure modes often require multiple stressors acting together. A solder joint might survive temperature cycling alone and vibration alone, but fail when thermal expansion and mechanical fatigue act in combination.

Envisys altitude chambers simulate everything from sea-level humidity to low-pressure, low-temperature conditions at high elevation. Thermal shock systems enable rapid transitions between temperature extremes, accelerating the thermal fatigue mechanisms that cause premature failures in field use.

For chemical exposures, Envisys systems enable cyclic corrosion testing that replicates field conditions better than continuous salt spray exposure. These cycles, alternating between salt fog, humidity, and drying, accurately simulate the corrosion mechanisms when vehicles are driven through salted roads then parked.

Different automotive subsystems require different testing approaches. Battery validation demands specialized chambers with enhanced safety features. Exterior components need rain and spray testing to validate sealing. Interior components require evaluation against temperature extremes and humidity from direct sunlight exposure.

Envisys works with manufacturers to develop test protocols specific to their components and use cases, identifying the environmental stressors most relevant to each application and designing testing to efficiently expose vulnerabilities.

Moving Forward with Environmental Validation

The automotive industry’s rising warranty costs suggest that environmental testing needs to evolve in parallel with vehicle technology. As electronics content increases and new technologies like electric powertrains introduce novel failure modes, the testing approaches that worked for simpler vehicles no longer provide adequate reliability assurance.

For automotive manufacturers facing both increasing complexity and decreasing tolerance for reliability issues, environmental testing represents not an expense to minimize but a strategic investment in product quality. The manufacturers who get this right won’t just reduce warranty costs they’ll build the reputation for reliability that creates competitive advantage in markets where quality increasingly differentiates successful products from expensive mistakes.

The global

The global