ENHANCING ENVIRONMENTAL AND

PERFORMANCE STANDARDS:

1) BACKGROUND

Envisys Technologies Pvt. Ltd., a leader in environmental test chambers in India, has consistently demonstrated a commitment to innovation and sustainability. With global regulatory shifts and rising environmental consciousness, the refrigerant industry is undergoing a major transformation. Traditionally, many Envisys systems have used R404A, a high-performance but high-GWP (Global Warming Potential) refrigerant.

In 2025, recognizing the need for a more sustainable and future-proof solution, Envisys announced a complete transition from R404A to the next-generation R449A refrigerant across all upcoming product lines.

2) PROBLEM STATEMENT

The use of R404A, though effective in thermal performance, comes with serious environmental drawbacks:

- Extremely high GWP (3922), making it a major contributor to global warming.

- Increasing regulatory pressure globally to phase out high-GWP refrigerants.

- Limited long-term compliance with emerging international sustainability standards like F-Gas

Regulations and Kigali Amendment to the Montreal Protocol.

These constraints created an urgent need for an eco-friendlier, energy-efficient, and regulation-compliant

alternative.

3) THE SHIFT: WHY R449A?

| Refrigerant | R404A | R449A |

|---|---|---|

| Composition | R143a / R125 / R134a (%44 / %52 / %4) |

R32 / R125 / R134a / R1234yf (%24 / %25 / %26 / %25) |

| ODP | 0 | 0 |

| GWP | 3922 | 1282 |

| Critical temperature (°C) | 345.2 | 357 |

| Critical pressure (kPa) | 3728.85 | 4662 |

| Boiling point (°C) | 226.7 | 227.2 |

| Liquid density (kg/m3) at 0°C | 1150.59 | 1198 |

| Vapor density (kg/m3) at 0°C | 30.32 | 22.43 |

| Liquid Cp (kJ/kg·°C) at 0°C | 1.39 | 1.417 |

| Vapor Cp (kJ/kg·°C) at 0°C | 1 | 0.976 |

| Liquid heat transmission coefficient (W/m·°C) at 0°C | 73.15 | 91.83 |

| Vapor heat transmission coefficient (W/m·°C) at 0°C | 12.82 | 12.03 |

| Liquid viscosity (Pa·s) at 0°C | 179.7 | 190.5 |

| Vapor viscosity (Pa·s) at 0°C | 11 | 11.29 |

| Safety classification | A1 | A1 |

Envisys chose R449A as the strategic replacement for R404A due to its:

- Lower GWP (1397) ~65% reduction compared to R404A.

- Zero Ozone Depletion Potential (ODP).

- Drop-in compatibility for many existing systems, minimizing redesign costs.

- Improved energy efficiency and cooling performance, verified by third-party studies.

This shift is not just a technical upgrade – it reflects Envisys’ long-term environmental responsibility and

compliance strategy.

4) EXPECTED OUTCOMES

4.1) EnvironmentalImpact

- Reduction of overall carbon footprint from refrigerant use.

- Full alignment with India’s and global climate action goals.

- Improved corporate image and sustainability scores.

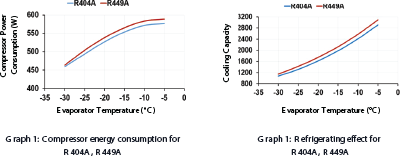

4.2) Operational Efficiency

- Higher cooling capacity and performance under various operating conditions.

- Reduced power consumption – beneficial in long-run testing applications.

- Lessrefrigerant massflow required – lower operational load.

4.3) Compliance & Future Readiness

- Prepares Envisys productsforfuture regulatory landscapes.

- Compatibility with upcoming standards across U.S., EU, and other export markets.

- Enhances confidence among international clients, especially in aerospace, automotive, and

electronicsindustries.

Conclusion:

| Metric | R404A | R449A | Benefit of R449A |

|---|---|---|---|

| Global Warming Potential (GWP) | 3922 | 1397 | ~65% lower |

| Cooling Effect | Baseline | +23% higher | Improved output |

| Energy Efficiency (COP) | Baseline | +5% higher | Lower energy use |

| Life Cycle Climate Performance | Baseline | ~5% lower | Greener systems |

| Exergy Efficiency | Lower | +5% higher | Less energy loss |

The adoption of R449A marks a significant step in Envisys Technologies’ journey toward sustainability

without compromising performance. Backed by scientific validation and real-world applicability, thistransition

enhances Envisys’ value proposition as a forward-looking manufacturer delivering reliable, green, and globally

compliant environmental testing solutions.

Let me know if you’d like this content formatted into a presentation, one-pager brochure, or website update – I

can help you structure each version accordingly.