In today’s market, environmental testing is no longer a compliance checkbox or an engineering ritual – it’s a business decision with measurable economic outcomes. Yet, many companies in India still approach testing the way they might approach a machine purchase – as a one-off transactional activity instead of treating it as a milestone strategic investment.

From electronics or semiconductor and automotive or EVs to aerospace or defence, the landscape of product development is changing. The complexity of testing requirements is increasing, but budgets, timelines, and internal pressures remain real. This makes the economics of testing decisions more important than ever before.

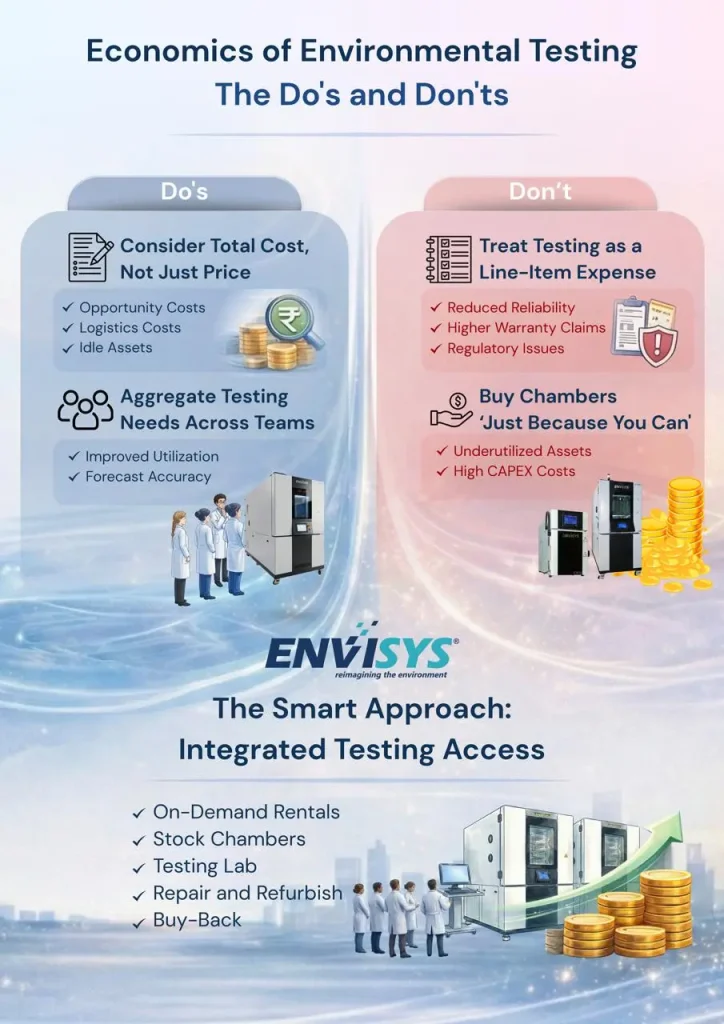

THE DO’S – MAKE TESTING WORK FOR YOUR BUSINESS

1) Think in Terms of Total Cost of Testing, Not Just Price

Many companies compare only the pre-test price or a one-time chamber cost, ignoring:

- Opportunity cost of missed deadlines

- Hidden travel & logistics costs

- Lab queue delays

- Cost of idle assets

- Depreciation of owned chambers

A more holistic view helps make smarter decisions that reduce Total Cost of Ownership (TCO) and improve ROI.

2) Leverage Flexible Access over Rigid Ownership

Environmental testing needs are rarely consistent. Many companies test intensively during

- New product launches

- Design Cycles

- Regulatory Validations

But during steady state, demand falls. In such cycles, flexible access to testing platforms – whether via on-site chambers or rental, shared facilities, or hybrid arrangements – often delivers better economics than outright ownership.

3) Aggregate Testing Needs Across Teams

Product teams often test in siloes. Consolidating testing demands across functions improves:

- Asset utilization

- Negotiating power with service providers

- Forecasting and planning accuracy

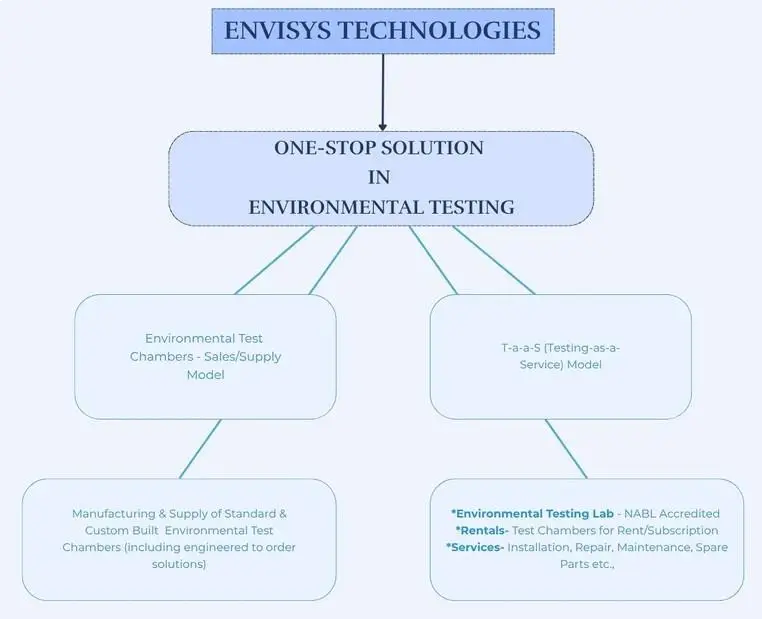

A one-stop platform for environmental testing such as that offered by Envisys Technologies Pvt Ltd enables organizations to aggregate demand efficiently and extract maximum economic value from testing investments.

4) Invest in Faster Turnaround and Confidentiality

Third-party labs often involve:

- Transport delays

- Waiting Queues

- Confidentiality Exposure

For strategic projects, having local testing access – either in-house via rental chambers or through an on-site platform – improves speed and reduces business risk.

THE DON’T – AVOID THESE COSTLY MISTAKES

1) Don’t Treat Testing as a Line-Item Expense

Environmental testing is not a variable cost you can optimize by cutting. It influences:

- Product reliability

- Warranty Claims

- Failure Avoidance

- Regulatory Compliance

Reducing testing rigor to save cost often leads to higher downstream expenses.

2) Don’t Buy Chambers “Just Because You Can”

Buying chambers ties up capital, incurs depreciation, maintenance, and requires technical support. Unless testing demand is predictable and continuous, ownership often results in under-utilized assets – a clear drain of ROI.

3) Don’t Ignore Local Context

In India, logistics, infrastructure, and supplier responsiveness vary widely. Sending parts to far-off labs might be cheap on paper but costly in practice due to:

- Transport risk

- Customs/Clearance Delays

- Lack of real-time visibility

Local access to testing infrastructure brings real economic value.

One Strategic Approach: INTEGRATED TESTING ACCESS

Companies that succeed in managing environmental testing efficiently increasingly rely on integrated testing access platforms such as Envisys Technologies Pvt Ltd One-Stop Environmental Testing Ecosystem which includes:

- On-site rental chambers

- Managed testing services

- Remote monitoring and reporting

- Flexible tenure options

- Predictable pricing models

This model blends CAPEX avoidance with predictable, controlled OPEX, enabling faster product validation and superior ROI.

Case in Point – Why Flexible Models Win in India

In an economic landscape where budgets are constrained and business outcomes matter more than engineering prestige, models that avoid heavy capital lock-in and provide on-demand access are naturally more compelling.

This is especially true for:

- Start-ups

- Micro, Small and Medium Enterprises (MSMEs)

- Project-based engineering teams

- High-growth manufacturing clusters (e.g., Bengaluru, Chennai, Pune, NCR)

Here, you pay for utility, not capacity – a fundamental shift in economic thinking.

Bottom Line

Environmental testing economics is about value, timing, and flexibility, not just price or ownership. Modern testing decisions should help companies:

- Reduced upfront capital

- Improve flexibility and responsiveness Shorten product cycles

- Minimize hidden costs Protect confidential IP

When approached strategically, environmental testing transforms from a cost centre to a competitive advantage.

![Standards Familiarity [Respondents vs Familiarity Level]](https://envisystech.com/wp-content/uploads/2026/01/Standards-Familiarity-Respondents-vs-Familiarity-Level.webp)

![Standards Familiarity [Count vs Confidence]](https://envisystech.com/wp-content/uploads/2026/01/Standards-Familiarity-Count-vs-Confidence-1024x529.webp)

The global

The global